Brief Information

Who we are

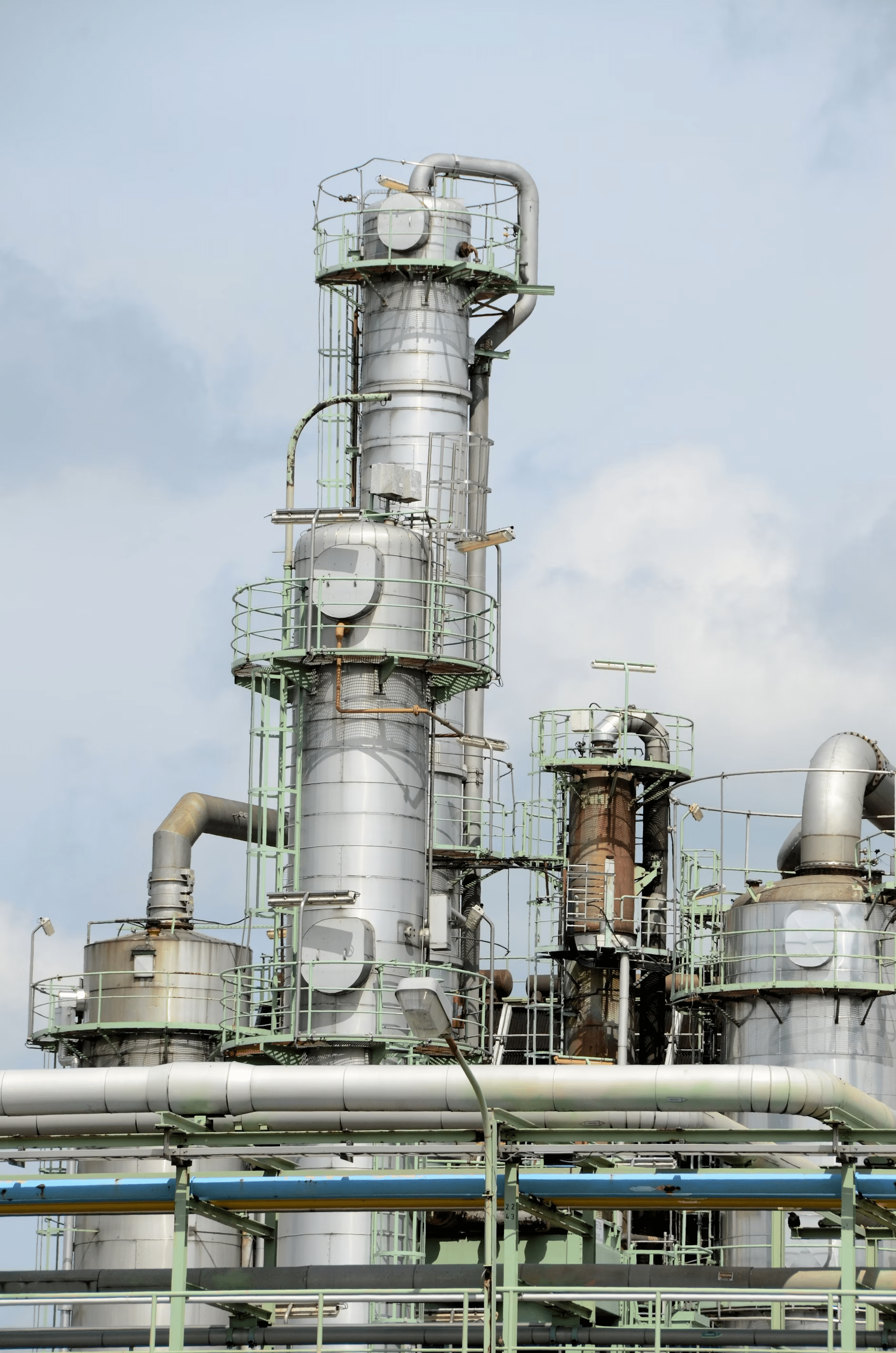

Expert Solutions for Building and Sustaining Vital Industries

- Fabrication & Erection of Structural steel Work

- Storage Tanks Fabrication & Erection Work

- Fabrication and erection of Piping such as CS/ SS/ Alloy steel including above ground and underground

- ARC Maintenance of Refineries, Petrochemicals, Fertilizers Plant etc.

- Turnaround(Shutdown) of Power, Chemical, Refineries and Petrochemicals etc.

About our Services

With highly professional and dedicated staff, we have the privileged of serving some of the industries leaders like M/s Reliance Industries Limited, M/s L&T, M/s Aarti Industries Limited, M/s Afcons Infrastructure Ltd. etc.

We are pioneer in executing projects at heights and in operating units of highly hazardous units of refinery and petrochemical plants which displays our strong control over HSEF.

We are construction contracting firm serving Oil & Refinery, Petrochemical units, Power Plants, Jetties and Marine terminals and Chemical industries.Our core experience is in the field of fabrication of process piping, steel structures and vessels, Erection and commissioning of piping, structures, vessels and columns, exchanger and rotary equipment’s.

Expertise in Working with all Types of Steels

- Carbon steel & LTCS

- Austenitic 3 series Stainless steel (SS 304, 310, 316, 321 and 347)

- low alloy steel ranging from P11 , P22 and P5 Alloy steel , A387 grade 11 , grade 22 and grade 5

- Grade 9, alloy steel and martensitic stainless steel SS410

Execution of work in Operating units of highly hazardous Refinery and Petrochemical complexes.

To minimize field work, we have fabricated and assembled steel structures modules with preassembled piping weighing up to 200 MT, shifting the same on multi-axle trailers and erection with cranes up to 800 MT capacity

Quality work execution in all areas

- Meeting Hydro test requirements

- Meeting water specification for hydrotest (salt ppm content and purity of water)

- Usage of Double calibrated pressure Gauges

- Ensuring proper Venting

Ensuring correct bolting

- Use of correct MOC of bolting

- Grade 4.6, 6.6, 8.8 and 10.8, B7, B7M, B8, B8M, B16, ASTM A453/A453M Grade 660 class A, Class B, Class C & Class D)

Ensuring proper Gasketing

- Correct rating Gaskets

- Correct Specification Gaskets

- Best practice to ensure proper insertion of Gaskets

Allocation Application of right correct Bolt Clamping force by

- Proper assembly Maintaining alignment as per ASME B31.1/B31.3.

- Using correct Bolting Technique like Calibrated Torquing/ Tensioning method.

- Right selection of Torque/Tensioning value

Execution Project with height up to 80 meters above Ground level

- We have executed number of projects at varying heights by meticulous planning and detailing

- Our Scaffoldings are controlled and among the best from both convenience and safety. Our scaffolding are designed to withstand 4 times the intended load with provision of escape route also

Modification, Replacement and Hooking up of Equipment’s

- In operating hazardous units of refinery and petrochemical complex.

- During shutdown with challenging schedule-

- replacement of pipes and equipment due to loss of thickness or metallurgy upgradation etc.

- Hooking of new equipment’s during Shutdowns in refinery and Petrochemical complexes within committed shutdown durations

- Dismantling and salvaging of piping, structures and Equipment’s.

- Dismantling of steel and RCC superstructure (pipe racks),dismantling of Vessels etc.

- Modification of civil foundations to Accommodate new Equipment

R S Fabricators Pvt Ltd has a Capacity of undertaking large Fabrication and Erection work at any location.

- Capacity to deliver 400 MT/month of steel structure Fabrication & assembly at a single location

- 350 inch dia/ day of piping Fabrication, 1000 inch meters/day of Piping Erection at a given location

- 400 MT/month of equipment Erection/dismantling

Special Work

- Weld overlays inside Piping and Vessels with exotic Metallurgy like Inconel etc.

- Non-Destructive examination – UT and Radiography

- Metal forming – plate Rolling

- Heat treatment, Post Heating and PWHT